The Need for Basic Water Treatment

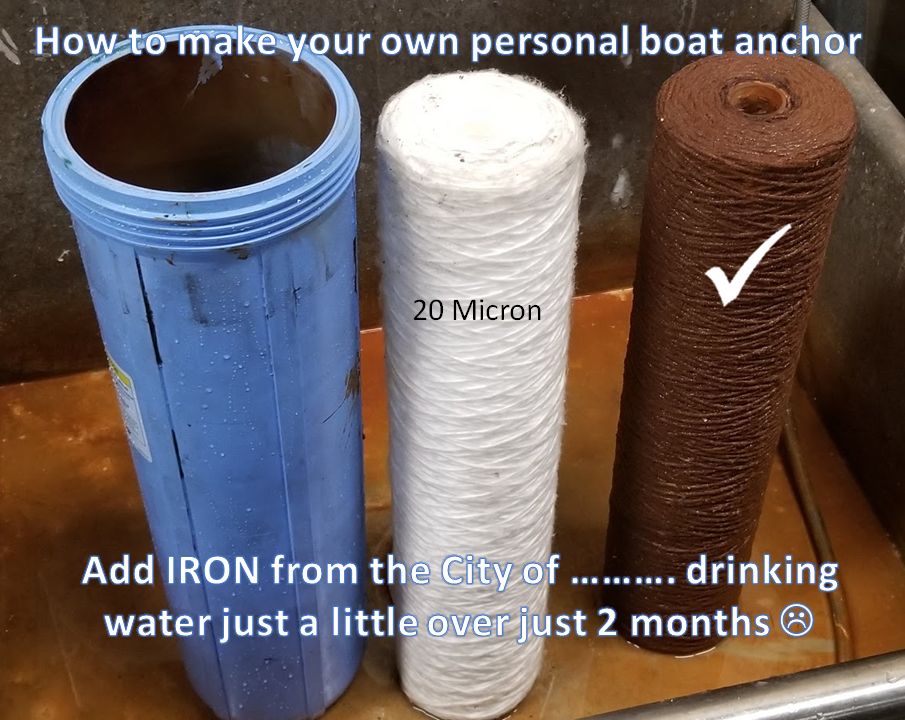

Water is the universal solvent, which means that in time, it will dissolve most minerals on and under the earth. This holds particularly true for man-made materials such as Carbon Steel (from Fe ore), Copper alloys and Galvanize pipe (Zinc Coated either hot-dipped or electroplated) and their associated equipment, which for the most part are on the waterside of the system. Tubing, pipes and flat surfaces of the same material that are exposed to water and oxygen will revert to their natural state in time.

Summary: Basic water treatment is used to prevent losses of metallic material (corrosion), scale formation (heat transfer losses) and preventing bio-film from forming on heat transfer services. The most important part arguably is the MICRO-BIO component of any water source that is used and treated, as it has a direct effect on the corrosion, scaling and fouling issues.

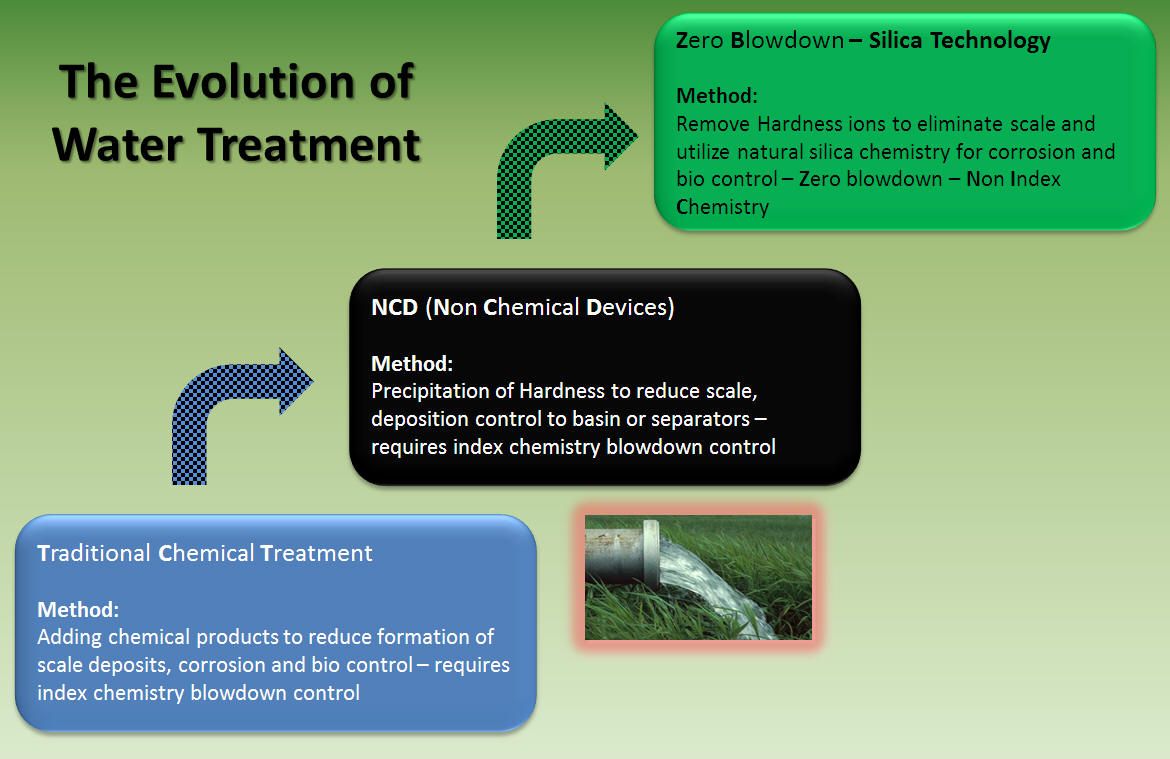

Water treatment has taken on many forms for over 100+ years now. We now have technology of various types to treat both boiler and cooling towers & heat exchanges. Most advances have been introduced for cooling systems in both tower design and hybrids that are made up of very high-tech evap media.

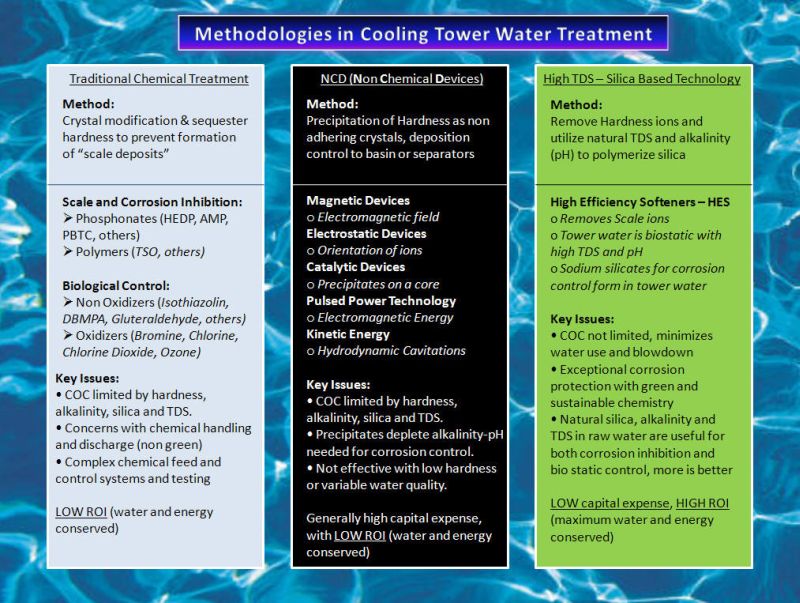

Methodologies in Cooling Tower Water Treatment

Traditional Chemical Applications

Non-Chemical Devices

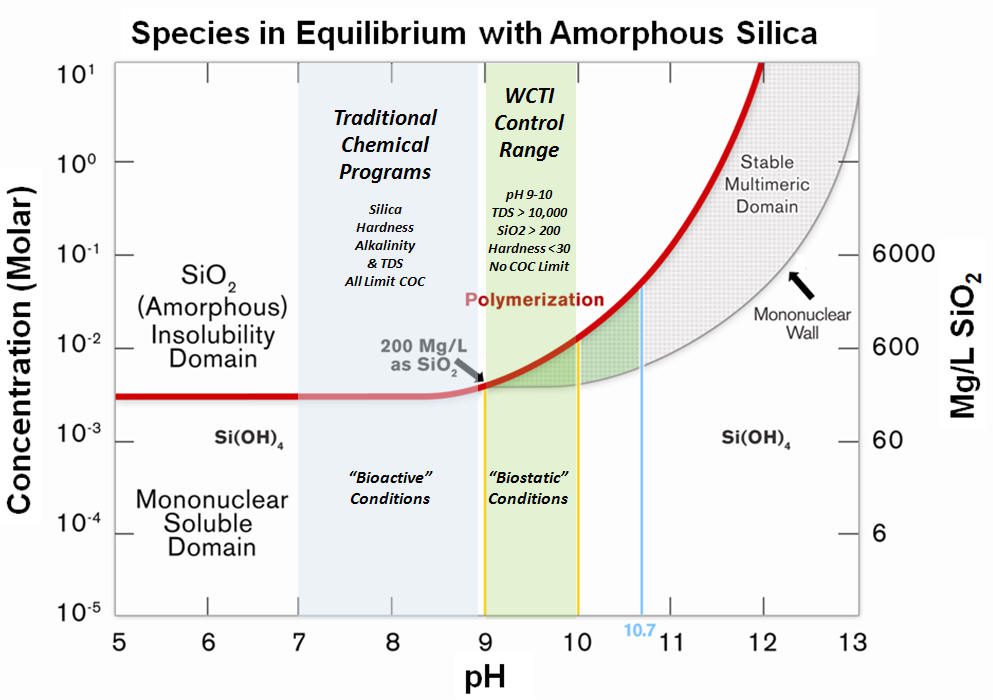

SiO2Tech

Some Extra Pictures for Discussion and Comments on Silica-based Technology

Every question you may think of and plenty you have not are linked here below to help you understand what WCTI has achieved throughout the world: